You've received a box of chocolates before, right—have you ever noticed how nice the box is? At CyGedin, we believe that what is inside a chocolate bonbon should be just as beautiful as when you open the package to reveal what is inside! Translation Let’s Look Together At How Chocolate Packaging Works.

Fancy chocolate-bonbon packaging is about making the chocolates look yummy outside and in. From glossy ribbons all the way down to colorful bows, every package is created to get you excited before you even take a bite!

At CyGedin we want all of our customers opening our boxes to feel like they are opening a premium, gift. That’s why we obsess over the details of everything we make, from the feel of the paper to the sound the wrapping makes when it crinkles in your hands.

Sweetening the deal even further offers when you go with CyGedin chocolates. Our packaging is designed to make gifting and receiving chocolate bonbons truly an experience. Great for any occasion whether it would be a birthday, anniversary or a nice surprise, here at Ceegees boxes we guarantee a smile for a box.

CyGedin takes how chocolate bonbons look very seriously, making them special. We work with the most accomplished designers to create a package you not only love to look at, but can use without making a mess. Our boxes are strong and make it easy for you to open them and devour your chocolates.

Yeah, this is a very critical chocolate bonbon packaging sale point in the confectionery world. Well-packaged boxes of chocolates can alter perceptions of the treats. Here at CyGedin, we understand that first impressions count which is why we take such pride in our packaging.

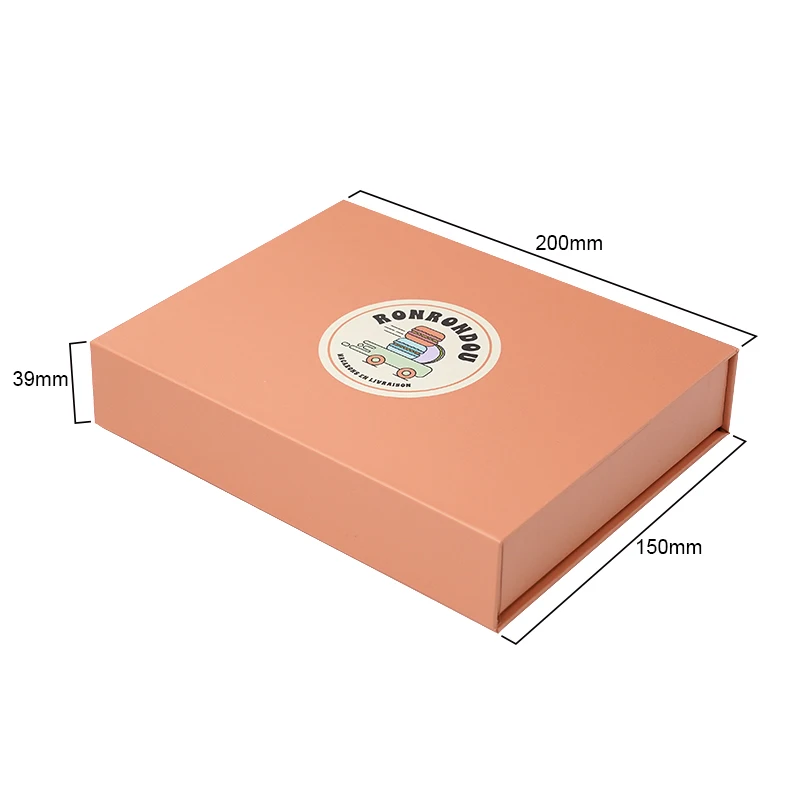

We specialize in creating tailored paper gift boxes for sectors such as cosmetics, luxury gifting, and electronics, ensuring that each design aligns with market demands and enhances brand identity.

We provide eco-friendly material options like FSC-certified paper and incorporate memorable unboxing experiences, proven to increase customer engagement, social exposure, and sales—as demonstrated by client success stories.

With production lead times as short as 7–10 days for urgent needs and the ability to scale from MOQ 500+ units, we offer both speed and flexibility to meet diverse business timelines and volume requirements.

From initial concept and structural engineering to material selection, printing, and functionality enhancements, we manage every step of the process—supporting projects from prototypes to bulk orders with consistent quality.